Plant

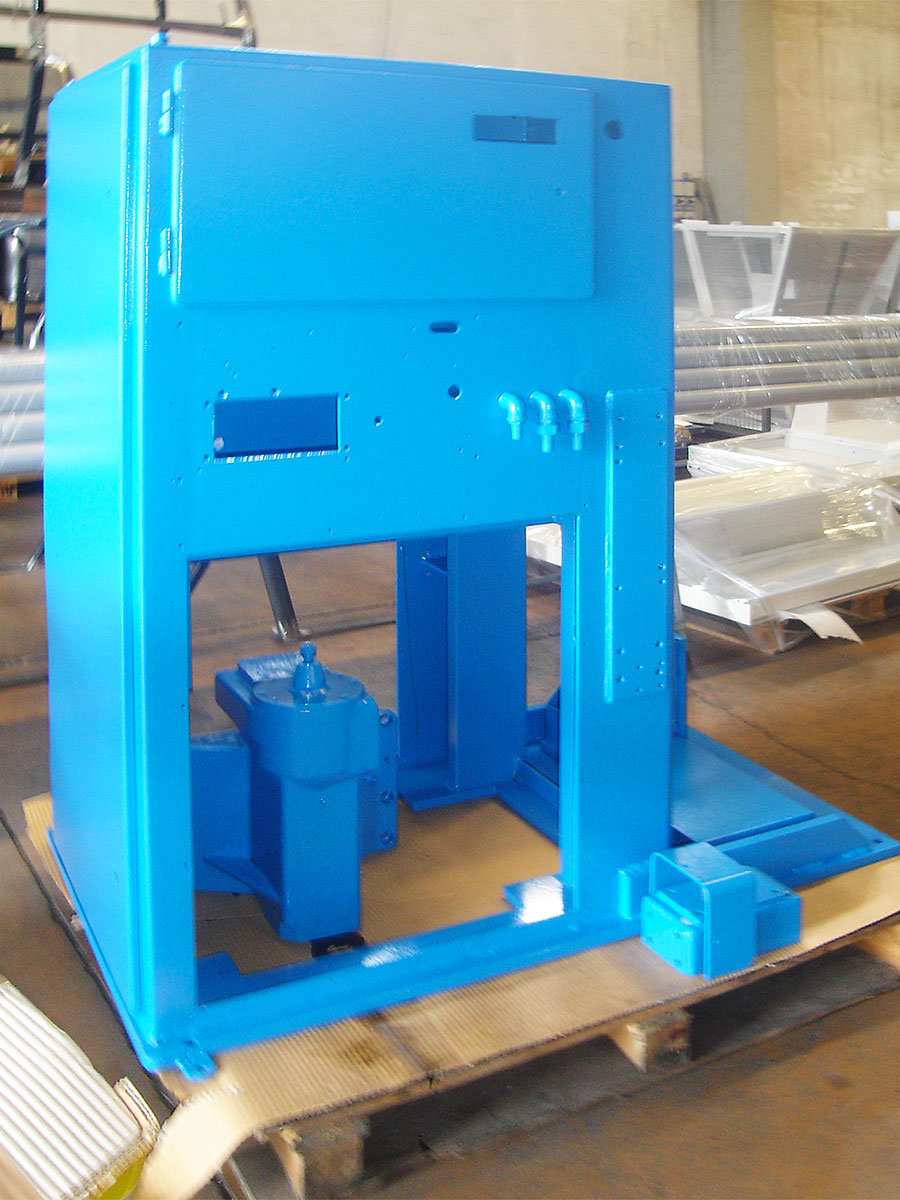

Industrial Powder Coating

We have two powder coating plants, a small one and a large one reaching the maximum overall size of 2000X2500X6000 mm, where mainly ferrous material is coated.

We process both large and small quantities of goods, using premium materials only, guaranteeing the quality of the final product and ensuring fast delivery service.

The smallest and most recent plant, presents 4 washing stages, which allows us both to reduce processing times and, thanks to the new low-impact cabin, the recycling of up to 98% of the excess powder, thus reducing the cost charge on large quantities of material, while maintaining high quality, meeting European quality standards for coating.

Our plants, with automatic hot washing for material phosphatizing and degreasing, are designed to allow fast and frequent colour changes, thus enabling us to meet specific customers demands such as a particular RAL colour or fast delivery service, even within 48 hours.

Powder coating

Definition

Powder coating is a process of coating metal surfaces with an organic film, carried out for decorative purposes and/or protection against corrosion and aggressive agents.

The workpieces are coated with coating powder composed of synthetic resins (e.g. epoxy powders), which adhere by electrostatic effect, and then transferred into an oven where, due to the high temperature, the coating first melts and then polymerises, resulting in an adherent and uniform layer on the metal surfaces.

Processes

Carpentry up to 10 quintals

Shop furnishing

Ladder and handrails for interior furnishings

Construction machinery

Food processing machinery

Agriculture machinery

Urban furnishing

Vacuum systems

Architectural structures

Treatments

High quality finishing

“Qualicoat” coating for outdoor equipment

Transparent antiquated effect

Thick peel coating for machinery

High quality architectural finishing

Coatings for food industry

Industrial powder coating line

1. Washing

Washing tunnel with water heated up to 60° and added with phosphating products and zinc products.

The parts enter a tunnel and are washed with water sprays fed by centrifugal pumps. The washing liquid is constantly recycled with replenishment by consumption, due to evaporation and drying of the wet parts. The water contained in the washing tank is heated (60°) and added with phosphating products and a product specific for zinc.

2. Rinsing

Rinsing tunnel with clean and cold water sprays, fed by centrifugal pumps.

3. Drying

Hot air recycling oven at a temperature of 140° for 20/30 minutes.

Drying takes place in a hot air recycling oven to ensure the material is completely dry and all remaining oil in the cracks is burnt off.

4. Visual inspection

The material is inspected for grease residue or any impurity.

5. Base coat application

Thermosetting powder coating is applied by layering and electrostatic depositing.

Thermosetting powder coating is a technology that allows paint to be applied without the need for solvents, based on the use of completely dry powder products applied by electrostatic layering and depositing.

6. Kiln firing

The cooking temperature is 180/190° for 25/30 minutes and depends on the material thickness.

7. Colour application

The second layer of thermosetting powder coating varies according to the specific colour selected by the customer.

8. Kiln firing

The cooking temperature is 180/190° for 25/30 minutes and depends on the material thickness.

9. Final product check

Tests are carried out to check the adhesion of the coating layer.

Check is performed through manual squaring tests and subsequent application of an adhesive film to assess the adherence of the coating layer. The thickness of the coated finishing is then controlled, and must not be less than 60/80 microns.

10. Packaging

The material is placed on pallets, with layers of cardboard and expanded polyethylene.

The material is placed on pallets, with layers of cardboard and expanded polyethylene and strapping bands to avoid any damage and be suitable for transport.