Plant

Industrial Sandblasting

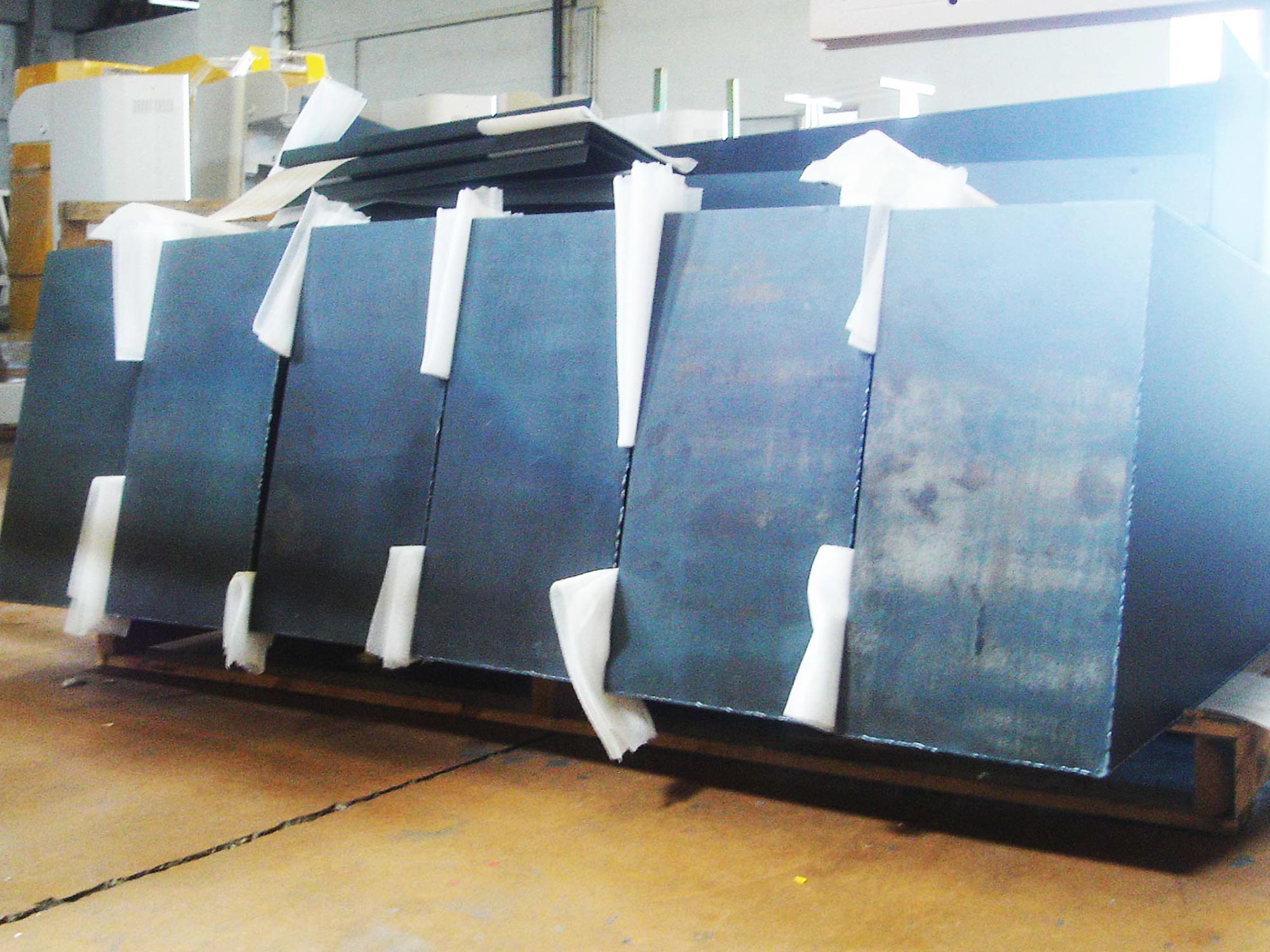

In our 2000x2500x6000 mm sandblasting plant, we are able to handle items of significant size, offering a large work area allowing us to effectively and efficiently process very large parts.

Through sandblasting, surface contaminants such as rust, coatings, oils, scale or other unwanted deposits are removed from the surface of treated metals, preserving the integrity of the treated surfaces.

An interesting aspect to note is the use of Garnet Sand as an abrasive in industrial sandblasting. Garnet Sand is a high-quality abrasive material renowned for its ability to remove surface contaminants effectively without damaging the underlying surface.

Sandblasting

Definition

Sandblasting is a mechanical process by which the most superficial part of a material is eroded through abrasion by a jet of sand and air. The process evens out the surface of metals, cleaning them thoroughly of scale, rust and residues, to obtain a finish that ensures good adherence for subsequent treatments. Sandblasting is typically performed on steel, cast iron, metal alloys in general, timber, ceramics, stone and marble; both for industrial mechanical and construction use.

Industrial

sandblasting system

Sandblasting is performed in our plant, using a high-pressure jet of sand, which, directed onto the metal surface, removes the encrusting material by impact and abrasion.

The treated surface is therefore clean, slightly rough, free from rust, residue and dirt, and therefore suitable for retaining the colour of the following coating process.